MELTING

Our solutions

- Improve productivity

- Improve operator safety

- Reduce the wear or breakage of consumables (graphite electrodes, cooled panels, refractories, etc.)

- Limit the indirect contribution of carbon (burners, etc.)

- Reduce power consumption

- The electric arc furnace

- Scrap metal preheating

- The “Torus” concept

ArcInnov Technologies

The electric arc furnace

- The tilting platform

- The shell and its roof

- The superstructure

- The electrode holder

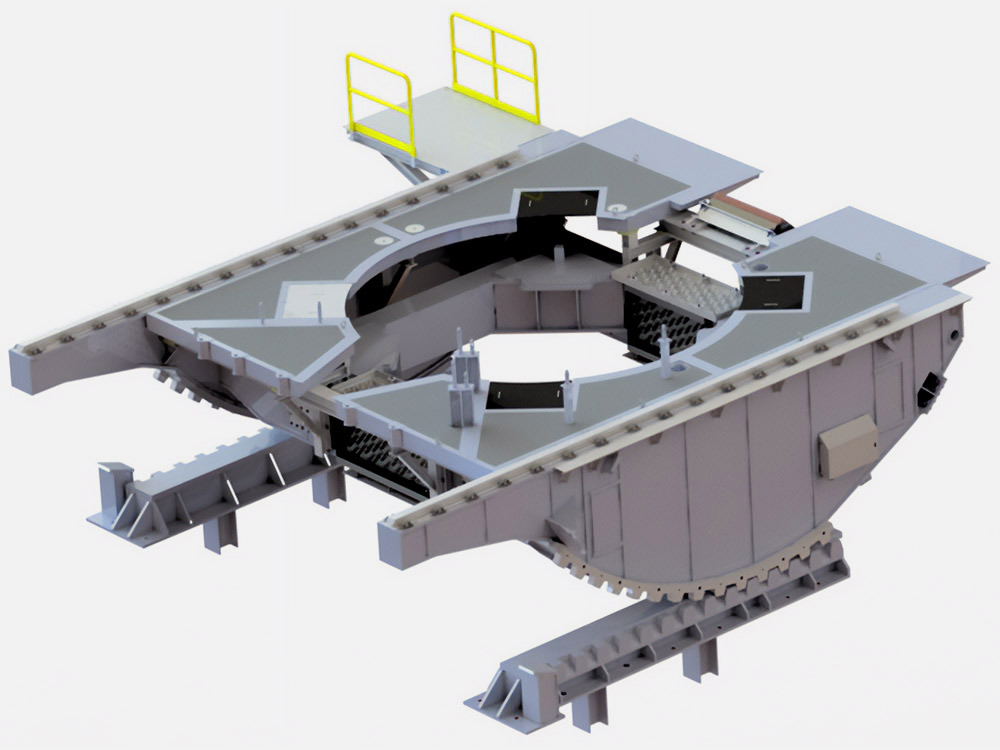

Tilting platform

The tilting platform or “cradle” is the main frame supporting the furnace shell and sometimes the electrode holder and allowing the so-called “casting / deslagging” movement of the furnace. It is a large mechanically welded part that can weigh several tens of tons, which requires precise manufacturing and considerable rigor and know-how when handling it.

Its design must consider :

- Significant mechanical stresses

- The risks associated with liquid metal breakthroughs

- Transport and handling constraints

EQUIPMENT :

Tilting platform for 1t pilot furnace

STUDY CONTEXT :

Design of a platform with pivoting around the spout

SOLUTION REALIZED :

Mechanically welded platform carrying the shell assembly and electrode holder mechanism and roof suspension arm

The shell and the roof

- Shell and roof with or without cooled panels

- Concrete or brick filling

- Shell with pouring spout, off-centre or apsed pouring holes

- Technical choice

- Geometric sizing

- Definition and realization drawings, supply

- Thermal studies…

EQUIPMENT :

Roof equipped for 1t pilot furnace.

STUDY CONTEXT :

Realization of a complete pilot installation

SOLUTION REALIZED :

Monolithic concrete roof fully equipped (fumes collection, materials feeding, etc.) and optimal sealing.

EQUIPMENT :

Roof equipped for 1t pilot furnace.

STUDY CONTEXT :

Realization of a complete pilot installation

SOLUTION REALIZED :

Monolithic concrete roof fully equipped (fumes collection, materials feeding, etc.) and optimal sealing.

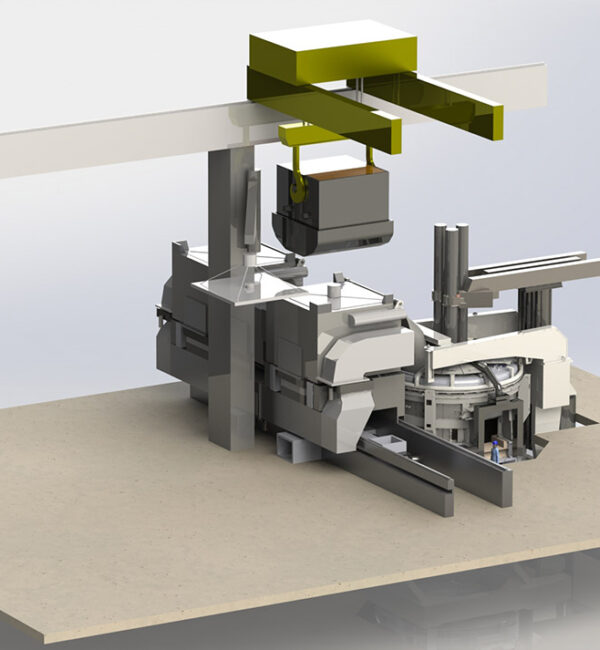

Superstructure

The main element of the upper part of the arc furnace, the superstructure acts as the supporting structure for the roof suspension arm assembly and for the electrode holder mechanism.

It is generally a mechanically welded assembly of large dimensions subjected to very high mechanical stresses.

EQUIPMENT :

Superstructure for 1t pilot furnace

STUDY CONTEXT :

Realization of a complete pilot installation

SOLUTION REALIZED :

Superstructure on slewing ring

EQUIPMENT :

Superstructure for 40t furnace

STUDY CONTEXT :

Original superstructure replacement

SOLUTION REALIZED :

New superstructure with water cooled suspension arms.

The electrode holder

Certainly, the most complex equipment that makes up the arc furnace. It can be made up of 3 arms for a three-phase alternating current (AC) furnace or 2 arms for a direct current (DC) furnace.

In most cases, the arm has at least one vertical up and down movement. This movement can be ensured by different types of actuators :

- Hydraulic cylinder

- Steel cable and electric gear motor

- Ball screw and servomotor…

The electrode holder arm has two roles :

- The current supply to the electrode (tube bus, conductive arm,)

- Electrode support (clamp)

EQUIPMENT :

Complete set electrode holder for 1t DC pilot furnace

STUDY CONTEXT :

Realization of a complete pilot installation

SOLUTION REALIZED :

Electrode holder arm assembly for Ø100 electrode (vertical and tilting movements), current supply by tube-bus and injection of inert gas by the electrode

ArcInnov Technologies

ECOFEEDER an ingenious solution for preheating scrap

- The preheating of scrap metal by recovering the “off-gas” from the furnace

- Purification of gaseous effluents by incineration of combustible products (fats, oils, paints, etc.) and integrated post-combustion participating in the heating of scrap metal

- The possible use of the energy remaining in the “off-gas” after preheating by appropriate applications (DRI reheating, steam turbine, etc.)

EQUIPMENT :

Steelmaking plant (France)Tilting platform on cradles for 40t furnace

STUDY CONTEXT :

Replacement of the existing and aging platform

SOLUTION REALIZED :

Fabricated design platform with a modern and lighter design